Solution – Smart Factory

OUR SOLUTIONS

About Sector

Smart factory involves the use of digital technology including the Internet of Things, Big Data, Artificial Intelligence, Advanced Robotics, Virtual Technologies, 3D Printing and Cloud Computing. These technologies with the aim of keeping costs down while improving process efficiency, quality, reliability and safety, could be described as a smart factory. Digitally connected smart buildings can meet these changing needs, such as reducing carbon emissions and pollutants, increasing efficiency and creating a friction-less, end-to-end experience. Smart, connected buildings help industry leaders fabricate safer, more productive environments for their employees.

Data Collection

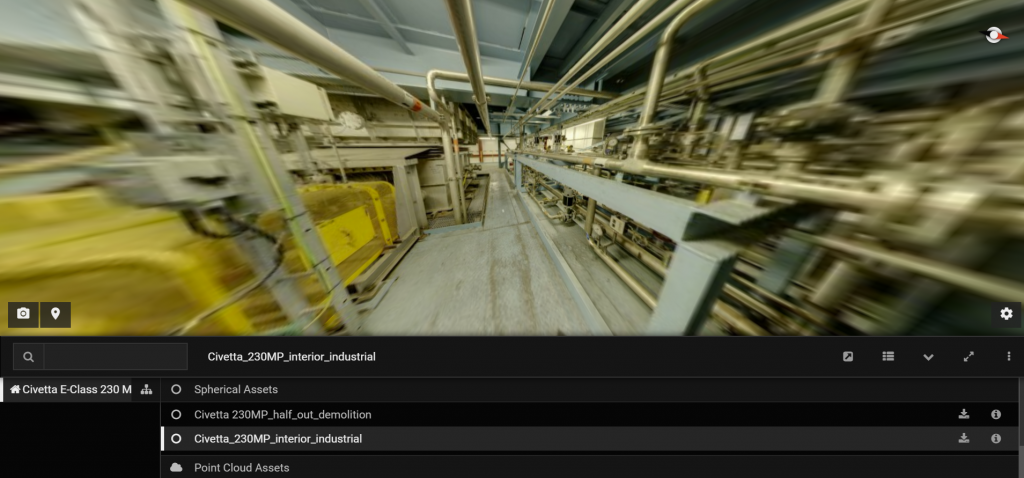

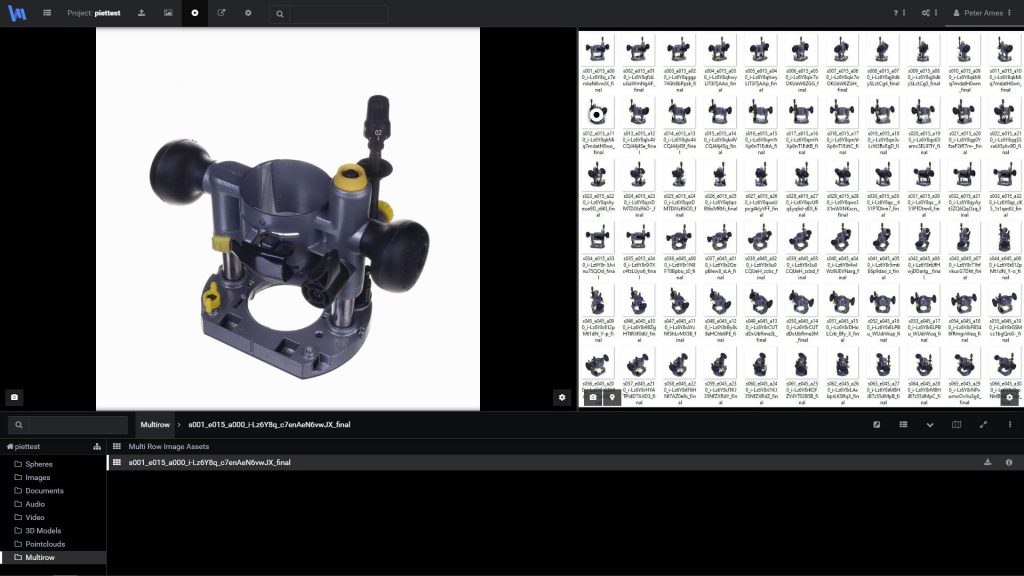

Civetta is commonly used to capture indoor, outdoor or underground factory space and thus produce 360×180° VR tour and 3D models for the digital factory. The I-Detic is further used to capture tubes, frames, objects to add further accuracy to the model. The I-detic is also used to produce 2D/3D digital twins for products and production assets of the factory place. Machine and equipment in the production line can be digitally recorded and accurately documented. Both the hardware can be operated in critical situations with the simple capturing method. Staffs in the factory can capture digital data periodically by themselves right after simple training. The I-Detic is IP68 waterproof and radiation-free, which can be used for inaccessible regions in the factory place.

Data Management

The VAM2 framework involves capturing 360° HDR panorama photograph of remote assets that can be combined in VAM2 to create virtual interactive walk-throughs. Associated data or files can be added and accessed from within these images, providing a highly intuitive recording, editing, sharing and presenting the information.

The VAM2 platform encompasses multiple types of information. It allows both synchronous and asynchronous, face-to-face and distant collaboration, communication, and planning. It can also be linked with other client systems, databases and live data feed, thus becoming a knowledge portal.

Here are some of the assets that might be collected to create a digital twin for the offshore platform:

3D point clouds and mesh model, with measurement data

360 HDR panorama image(JPG), with measurement data

Other high-resolution images of the scene and objects

machine evaluation report

item spin 360° images and 3D models

VR training set

Standardised videos and 360° videos

Audio

other office documents or media

digitalised and scanned files

3D simulated model, animation or videos

Safety inspection plan

Services

Implications

- 2D 360×180° visual tour

- 3D visual tour via point cloud or mesh (Visualise radioactive substance in real space)

- Digital record for factory layout duplication across different locations.

- Digital twins records of area and production assets, resource management

- Keep track of project progress, such as development and decommissioning design activities

- Remote planning for production lines (simulation and testing)

- Human capital management

- Visual Inspection (add comments, notes, HDR image filter and surface analysis)

- Manual Diagnostics (scheduled equipment inspections are expensive and inefficient strategy for detecting mal-functions in advance.

- Visual maintenance (with label and URLs for sharing)

- Physical measurements ( high accuracy, compatible with laser or any other methods)

- Communication and file transfer (offshore/onshore)

- Annual analysis and evaluation (VAM2 portfolio as zipped file or URL webpage)

- Allow structural engineers to functionally design new supporting frames or components that best fit the scene

- Low accountability (time-based, scheduled maintenance contracts provide little transparency into maintenance performance and ROI).

- Asset performance visibility (without visibility into building performance, business leaders are unable to track or validate optimization strategies).

For product/item management

- 2D/3D record of products/items – 360 VR quick snapshots and 3D models

- Directly connect barcode/ID with all other item-related assets via name, label, folder structure and hyperlink

- Visual and digital asset documentation of product design and change record

- Product portfolio sharing with contractors and third parties

Examples and case studies

- [China] Alibaba Group, one of the world’s largest retailers and e-commerce companies, used VAM2 for a product management project to manage automatically captured product photos, videos and 3D models.

- [Korea] A Korean factory uses the Civetta to make 2D/3D digital twin of their factory, to use the VAM2 portfolio as a reference for duplicating the same factory layout for a new branch in another country

- [Germany] The Pfaff factory uses both the Civetta and VAM2 to digitally record the entire factory area for digital documentation, project communication and reconstruction planning.

Training & Inspection

The introduction of a visual asset management system will also improve the training of operators, as training can be carried out in virtual factories that faithfully reproduce real conditions, with simulated failures and risky situation, thus support the prevention of occupational hazards. The Visual Asset Management VAM2 system enable users to digitally and visually connect different types of assets together, including VR panorama, 3D models, documents, audio, videos and many more. The integration of sounds and videos enrich one’s understanding of the factory situations.

With the Visual Asset Management VAM2 system, one would be able to attach different links of the sensor or analytic result to the 2D HDR panorama or 3D point cloud of an existing environment. Virtual and Argumented Reality in factory spaces are supporting by and reinforcing other forms of communication and processing technology, such as IoT, Big Data, machine learning algorithms and more. Operators and inspectors can work in a physical or virtual remote environment with a surrounding of information from 2D/3D assets as well as information from sensors installed in the assets of the production chain. Virtual inspection through the VAM2 platform can help to reduce travel, hostel, human capital and other critical expenses while ensuring the same quality of services are provided.

Previous Clients/Users

Pfaff Factory

Honda Motor Factory

- Alibaba Group

- More